Your cart is currently empty!

Method

The Transformation Process

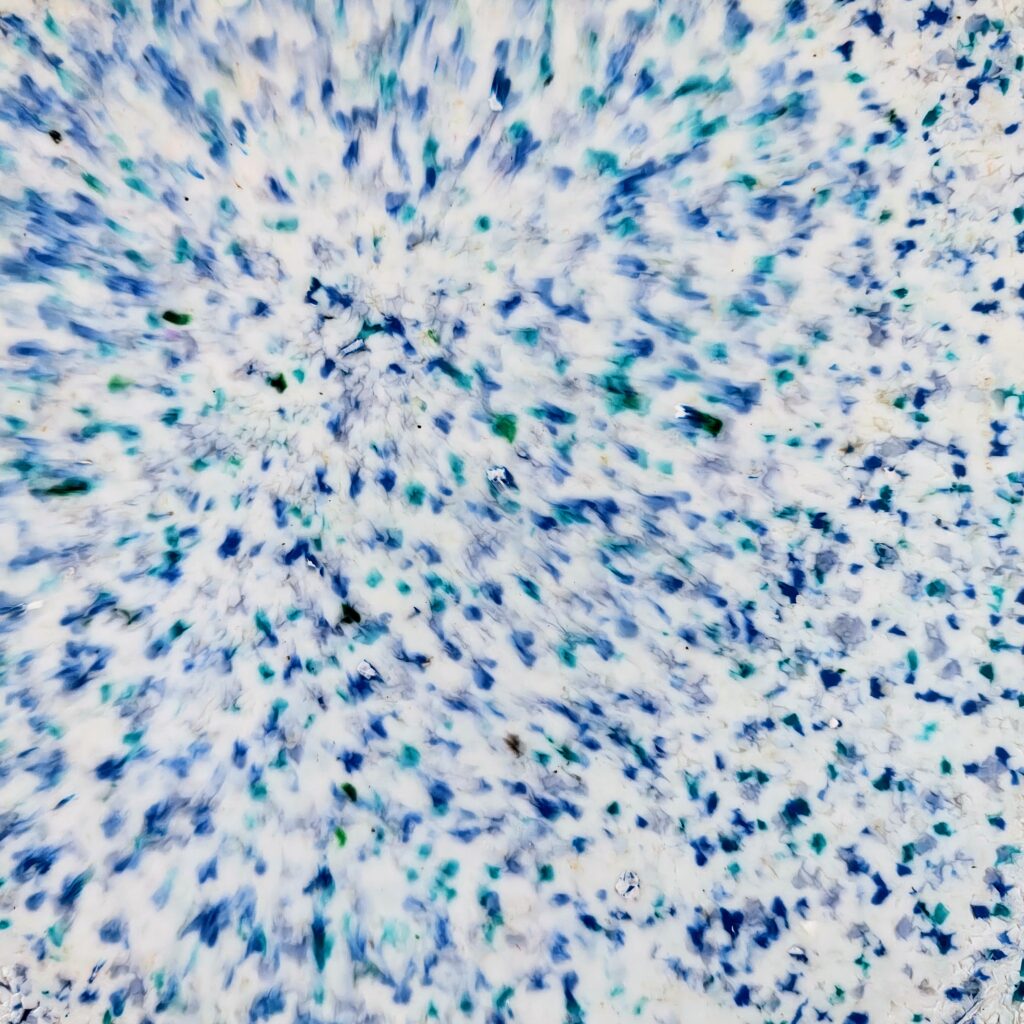

At Materia Redux, transformation begins with the right materials. Our method is precise, hands-on, and designed to give HDPE (#2) and PP (#5) plastics a second life. Every step of the process is intentional, ensuring that each creation is both sustainable and beautifully unique.

Collecting the Right Plastics

Not all plastics are created equal. At Materia Redux, we work primarily with:

- HDPE (High-Density Polyethylene) – #2

- PP (Polypropylene) – #5

We source these plastics locally, collecting them from households, cafés, kitchens, and institutions. Every donation comes with a story, making the material’s journey just as important as its transformation.

Sorting for Purity and Aesthetic Potential

Before anything is cleaned or shredded, materials are sorted carefully to:

- Separate HDPE and PP to prevent contamination.

- Organize by color, preserving clean, vibrant tones in the final product.

- Remove unusable plastics (PVC, PET, mixed-materials) that can’t be processed safely.

This ensures that every batch melts consistently and results in visually stunning creations.

Cleaning: From Waste to Raw Material

Every plastic piece is thoroughly cleaned to remove dirt, grease, and labels. The process involves:

- Hand washing with warm, soapy water to break down surface residues.

- Soaking in hot water to loosen stubborn labels and adhesives.

- Scrubbing and rinsing for a final deep clean.

- Air drying completely to prevent unwanted moisture during melting.

For tougher cases, plastics can be safely washed in a dishwasher—even if some pieces warp, they remain fully usable.

Shredding: The Transformation Begins

Clean, dry plastics are fed into a powerful plastic shredder. The goal is to create uniform granules (5-10 mm in size) for even melting.

- HDPE Granules: Opaque and solid, perfect for structure and durability.

- PP Granules: More fluid when melted, ideal for swirls and smooth finishes.

For special effects, some pieces are left larger, allowing them to melt into bold patterns when pressed.

Melting & Pressing: Creating New Forms

The shredded plastic is transformed into new designs using a heat press at precise temperatures:

- HDPE: 200-220°C for a solid, rigid result.

- PP: 180-200°C for a more fluid, glossy finish.

The process:

- Plastic granules are spread evenly into a mold lined with teflon sheets.

- The first press: Heated and pressed for 7-10 minutes on one side.

- The second press: The mold is flipped and pressed for another 7-10 minutes for even melting.

- Controlled cooling: The finished piece is placed in a secondary 80°C press to prevent warping.

This method ensures high-quality, smooth, and durable final products.

Shaping & Finishing

Once cooled, the plastic sheets and forms are refined:

- Edges are trimmed and smoothed using a hobby knife or sander.

- Final inspections ensure consistency in texture, thickness, and durability.

- Unique details and identifiers are added, ensuring traceability and storytelling in every piece.

From Raw Plastic to Functional Creations

At Materia Redux, plastic waste isn’t just recycled—it’s reimagined. By carefully sourcing, sorting, and processing HDPE and PP, we create one-of-a-kind products that blend sustainability with design.

Whether it’s a Chaotic Coaster, a Mosaic Tray, or a sculptural panel, each piece carries a history—one that started in waste and ended in something worth keeping.